Wholesale Dealers of Atex Certificated Circulation Heater - Heating trace customized – Weineng

Wholesale Dealers of Atex Certificated Circulation Heater - Heating trace customized – Weineng Detail:

Feature

Electric heat tracing, heat tape or surface heating, is a system used to maintain or raise the temperature of pipes and vessels using heat tracing cables. Trace heating takes the form of an electrical heating element run in physical contact along the length of a pipe. The pipe is usually covered with thermal insulation to retain heat losses from the pipe. Heat generated by the element then maintains the temperature of the pipe. Trace heating may be used to protect pipes from freezing, to maintain a constant flow temperature in hot water systems, or to maintain process temperatures for piping that must transport substances that solidify at ambient temperatures. Electric trace heating cables are an alternative to steam trace heating where steam is unavailable or unwanted.

Application

The most common pipe trace heating applications include:

Freeze protection

Temperature maintenance

Snow Melting On Driveways

Other uses of trace heating cables

Ramp and stair snow / ice protection

Gulley and roof snow / ice protection

Underfloor heating

Door / frame interface ice protection

Window de-misting

Anti-condensation

Pond freeze protection

Soil warming

Preventing cavitation

Reducing Condensation On Windows

FAQ

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.Can you overlap heat trace?

Do not overlap heat tape over itself. Do not wrap tape at a 90 degree bend. Install according to the instructions. Not all heat tapes can be used over plastic pipes.

3.Can you leave heat tape plugged in?

When the temperature drops, a small thermostat (built in on most models) calls for power that produces heat, then cuts off power after the temperature rises. You can leave these models plugged in. … The Consumer Product Safety Commission (CPSC) says they no longer collect data on heat tape-related accidents.

4.What is trace heating used for?

Trace heating is the application of a controlled amount of electric surface heating to pipework, tanks, valves or process equipment to either maintain its temperature (by replacing heat lost through insulation, also referred to as frost protection) or to affect an increase in its temperature – this is done by using

5.What is the difference between self-regulating and constant wattage heat trace?

Pipe trace constant wattage has a higher temperature output and tolerance. It consumes more power so it requires a controller or thermostat and some types can be cut-to-length. Self-regulating cables have a lower temperature output and tolerance. They consume less power, but require larger breakers.

Production Process

Markets & Applications

Packing

QC & Aftersales Service

Certification

Contact information

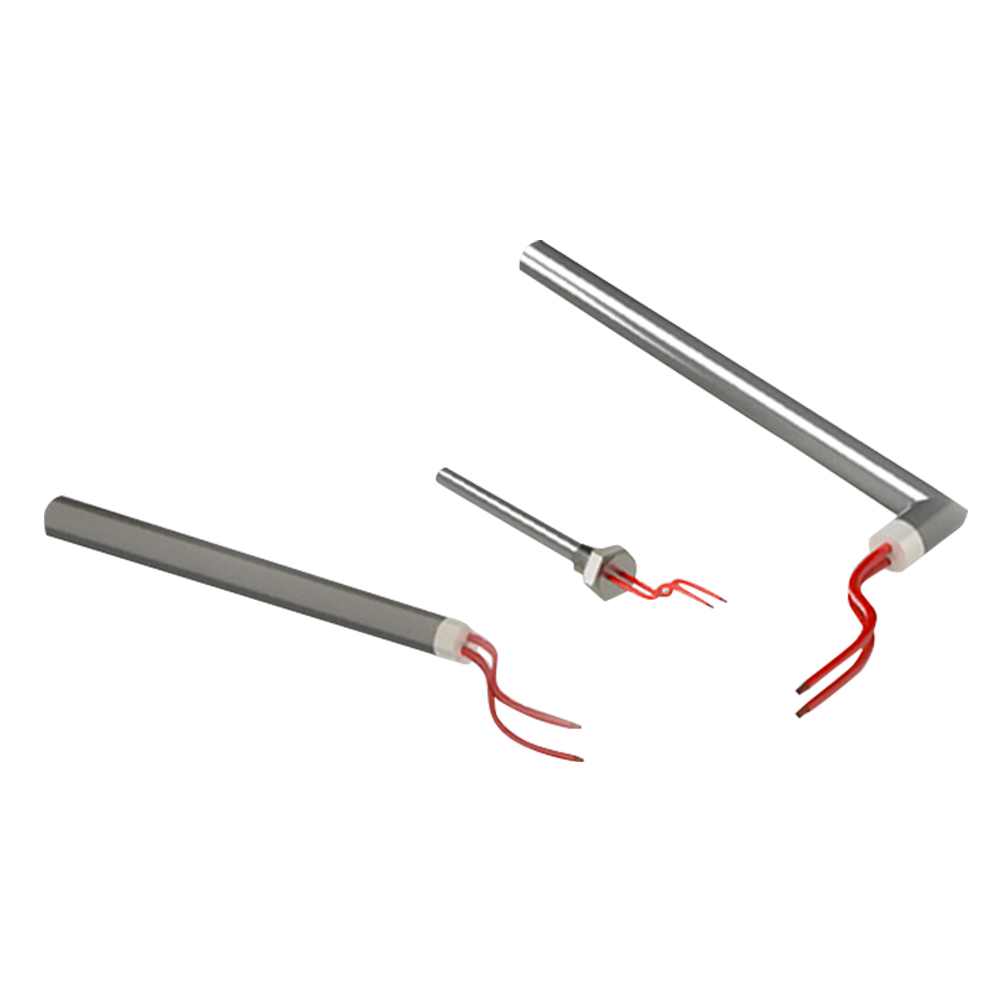

Product detail pictures:

Related Product Guide:

Our aim would be to fulfill our shoppers by offering golden company, very good value and good quality for Wholesale Dealers of Atex Certificated Circulation Heater - Heating trace customized – Weineng , The product will supply to all over the world, such as: Pakistan, Maldives, Uganda, Besides there are also experienced production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable solutions quality, increase customers' satisfaction and achieve win-win situation .

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!