Wholesale Dealers of Atex Certificated Circulation Heater - Flange type Industrial electric heater made in China – Weineng

Wholesale Dealers of Atex Certificated Circulation Heater - Flange type Industrial electric heater made in China – Weineng Detail:

Feature

Explosion proof construction: II2G Ex db IIC T1…T6 Gb

Range of ambient temperature:-60C /+60C

IP65 junction box protection

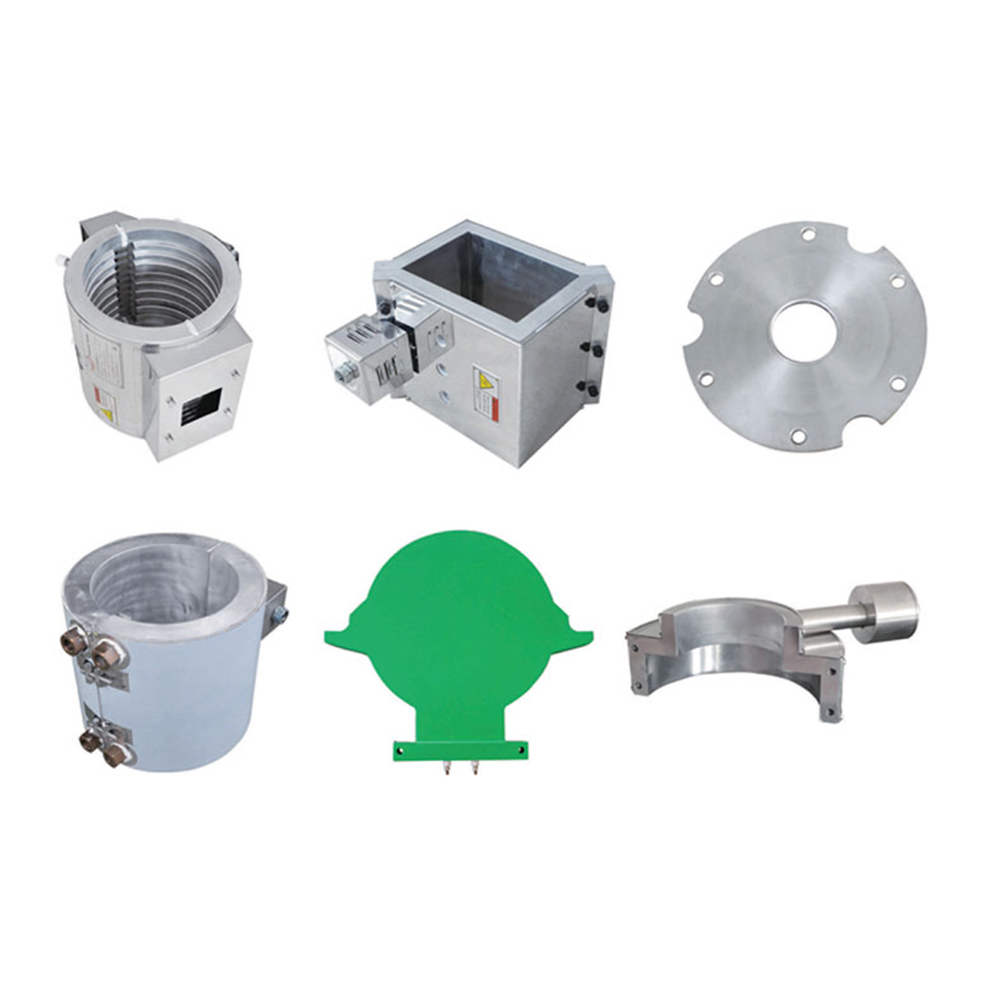

Standard elements available sheathed within: AISI 321, AISI 316, Incoloy800 and Inconel625

Multiple rows of elements for higher wattages

Flange mounted with removable stand pipe for an easy installation

Application

Storage tanks

Heating liquids in large tanks or vessels with low levels of product.

Heating liquids in underground tanks

FAQ

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.What are the available product certifications?

We have certifications such as: ATEX, CE, CNEX. IS014001, OHSAS18001,SIRA, DCI. Etc

3.What is a Flanged Immersion Heater?

A special heating element is connected to a flange. This is done with a hairpin bent element configuration. In some cases, tubular bugle elements are used. Tubing known as a thermowell is used to protect temperature probes, thermocouples and heating elements. Temperature readings are then transmitted to a control unit that powers the heat element on and off. For overload protection, a high limit sensor keeps the liquid from scorching or overheating and also serves to protect the flange immersion heater.

4.Why Are Flanged Heaters So Efficient?

Do you have a specific need to heat pressurized fluids? If so, you may wish to take a look at the many benefits that flanged immersion heaters can provide. In fact, a flanged heater is a highly efficient form of process heating and can be used for a variety of applications.

5.How long is the warranty time for your product?

Our officially promised warranty time is 1 year after delivering at best.

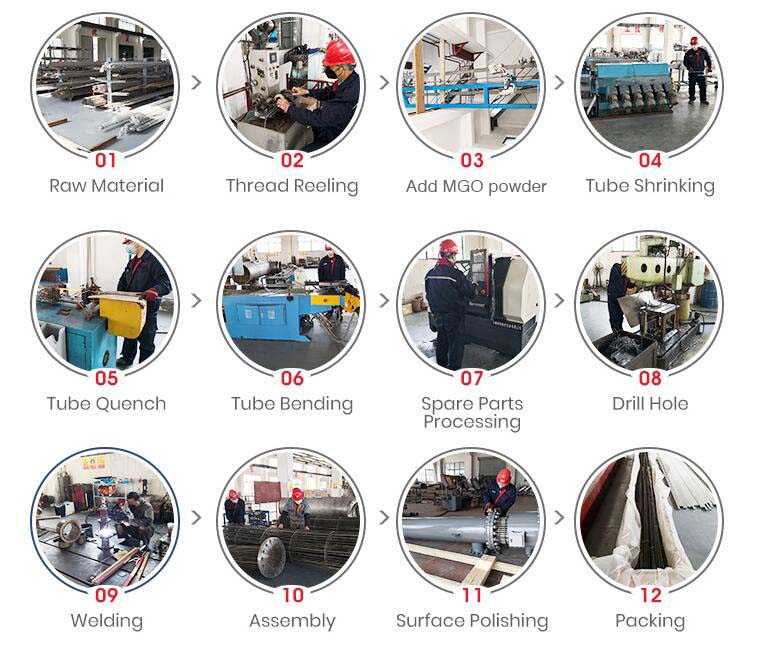

Production Process

Markets & Applications

Packing

QC & Aftersales Service

Certification

Contact information

Product detail pictures:

Related Product Guide:

We always continually offer you the most conscientious purchaser services, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Wholesale Dealers of Atex Certificated Circulation Heater - Flange type Industrial electric heater made in China – Weineng , The product will supply to all over the world, such as: Sri Lanka, Swiss, United States, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!