Top Suppliers Air Process Heater - Factory of industrial electric heater – Weineng

Top Suppliers Air Process Heater - Factory of industrial electric heater – Weineng Detail:

Feature

Explosion-proof electric heater is a kind of consuming electric energy converted into heat energy to heat the materials to be heated. During work, the low-temperature fluid medium enters the input port under pressure through the pipeline, and takes away the high-temperature heat energy generated by the electric heating element along the specific heat exchange channel inside the electric heating vessel, using the path designed by the principle of fluid thermodynamics. The temperature of the heated medium rises, and the high temperature medium required by the process is obtained at the outlet of the electric heater. The internal control system of the electric heater automatically adjusts the output power of the electric heater according to the temperature sensor signal of the output port. The medium temperature of the output port is uniform. When the heating element is overheated, the independent thermal protection device of the heating element immediately cuts off the heating power to avoid The over-temperature of the heating material causes coking, deterioration, carbonization, and in severe cases, the heating element burns out, effectively extending the service life of the electric heater.

Application

Heating of chemical materials in the chemical industry, some powder drying under certain pressure, chemical process and spray drying

Hydrocarbon heating, including petroleum crude oil, heavy oil, fuel oil, heat transfer oil, lubricating oil, paraffin, etc.

Process water, steam, molten salt, nitrogen (air) gas, water gas and other fluids that need to be heated.

Due to the advanced explosion-proof structure, the equipment can be widely used in explosion-proof places such as chemical industry, military industry, petroleum, natural gas, offshore platforms, ships, and mining areas.

FAQ

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.What are the available product certifications?

We have certifications such as: ATEX, CE, CNEX. IS014001, OHSAS18001,SIRA, DCI. Etc

3.How to Choose an Industrial Heater?

It is important to consider the specifics of your application prior to selecting the heater to use. Of primary concern is the type of medium being heated and the amount of heating power required. Some industrial heaters have been specially designed to function in oils, viscous, or corrosive solutions.

However, not all heaters can be used with any material. It is important to confirm the desired heater will not be damaged by the process. In addition, it is necessary to select an electric heater that is appropriately sized. Be sure to determine and verify the voltage and wattage for the heater.

One important metric to consider is Watt Density. Watt density refers to the heat flow rate per square inch of surface heating. This metric shows how densely the heat is being transferred.

4.What are the available heater fange type, sizes and materials?

WNH industrial electric heater, flange size between 6″(150mm)~50″(1400mm)

Flange standard: ANSI B16.5, ANSI B16.47, DIN, JIS (Also accept customer requirements)

Flange material: Carbon steel, Stainless steel, Nickel-chromium alloy, or other required material

5.What are the available element sheath materials?

Available sheath materials include stainless steel, high nickel alloy and many others.

Production Process

Markets & Applications

Packing

QC & Aftersales Service

Certification

Contact information

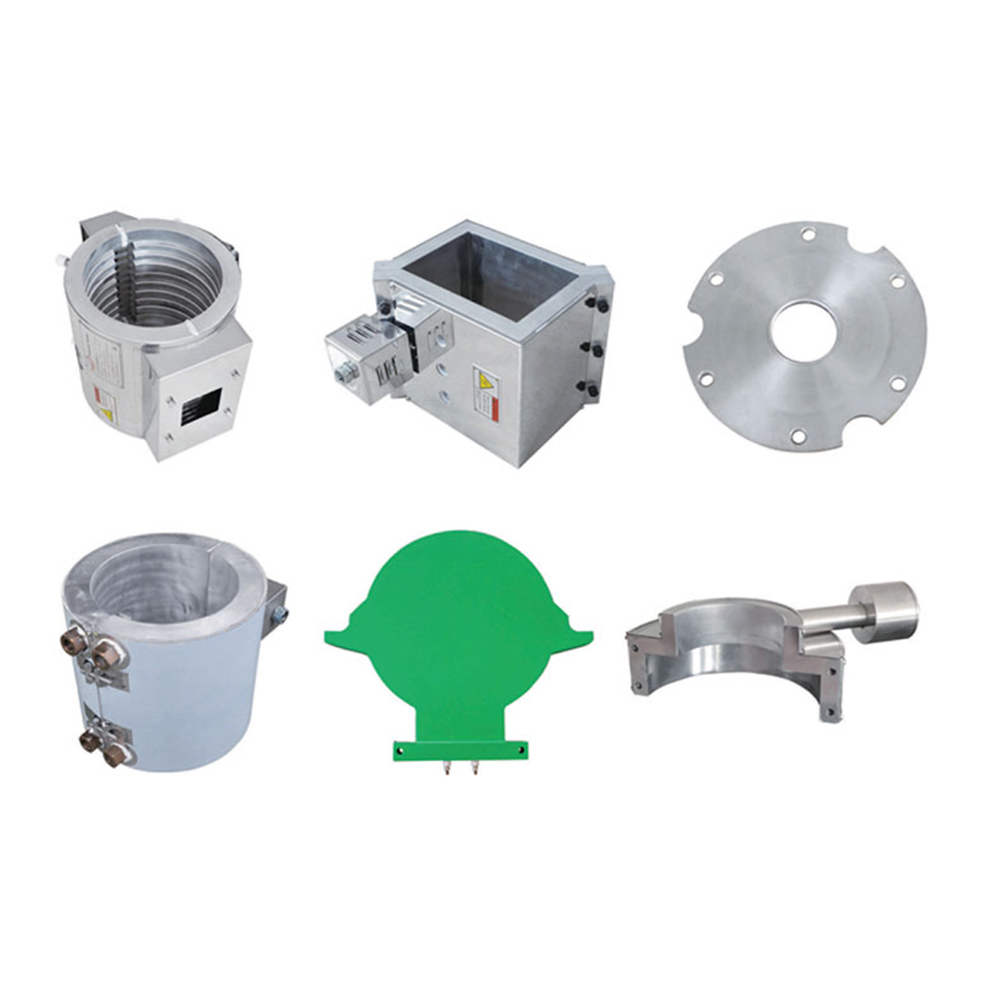

Product detail pictures:

Related Product Guide:

We have been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Top Suppliers Air Process Heater - Factory of industrial electric heater – Weineng , The product will supply to all over the world, such as: Singapore, Greenland, Niger, We have a dedicated and aggressive sales team, and many branches, catering to our main customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.