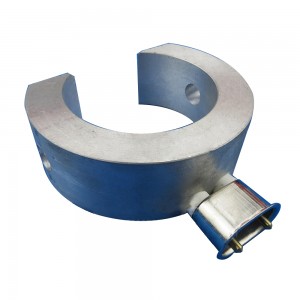

Mica band heater

The heating element is insulated within a mica core enclosed in a metal sheath which provides exceptional insulation, dielectric strength and heat transfer capability for faster heat up and longer heater life.

Mica Band Applications:

Plastic extruders

Injection molding machines

Blown film dies

container pipe

tank heating

Labs

Restaurant equipment

Pharmaceutical industries

Food industries

other cylinder heating applications

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.What are the available product certifications?

We have certifications such as: ATEX, CE, CNEX. IS014001, OHSAS18001,SIRA, DCI. Etc

3.Can Mica be heated?

Mica heating elements are a popular choice in various heating applications due to their high temperature capabilities of up to 600°C. ... Mica heaters are made using thin sheets of mica, allowing for low thermal mass and extremely quick heat-up times.

4.How does a band heater work?

Band heaters are ring-shaped heating devices that clamp around a cylindrical element. Heat transfer from band heaters occurs via the conductive method. Most band heaters clamp around the outer diameter of a cylindrical element and heat the element from the outside.

5.How do mica heaters work?

When mica is heated to a certain temperature, the electromagnetic rays are emitted into the room. The electromagnetic rays then heat up the room. The heating effect the rays have on the room is similar to sunlight. It provides soothing heat, radiant heat, much like infrared heaters do.