Manufacturing Companies for Explosion Proof Industrial Electric Heater - OEM industrial tubular heating elements – Weineng

Manufacturing Companies for Explosion Proof Industrial Electric Heater - OEM industrial tubular heating elements – Weineng Detail:

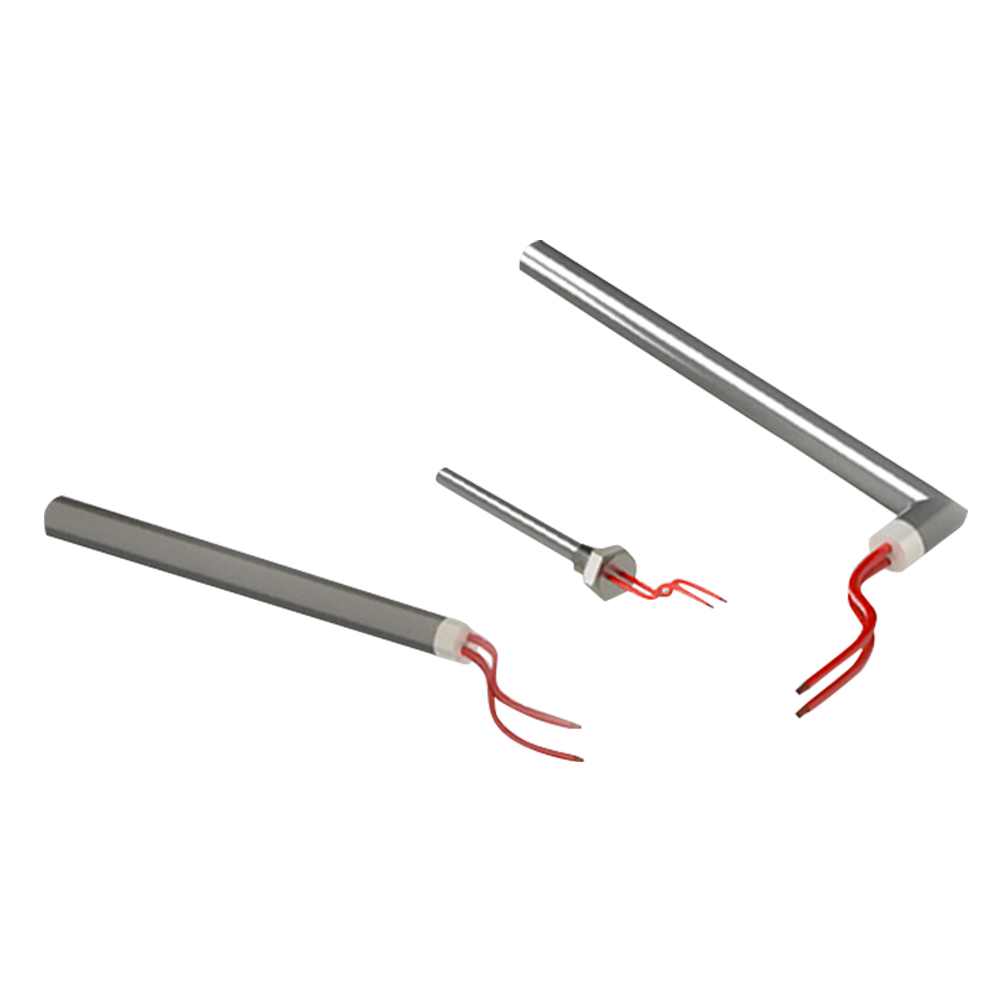

Feature

High quality raw materials:

Ni80Cr20 resistance wire.

UCM high purity MgO powder for high temperature application.

Tube materials available in: INCOLOY800/840, INCONEL600, Hastelloy, 304, 321, 310S, 316L and etc.

Key technical properties:

Leakage current : less than 0.5mA under operating temperature.

Insulation resistance: cold state ≥500MΩ; hot state≥50MΩ.

Dielectric strength: Hi-pot>AC 2000V/1min.

Power Tolerance : +/-5%.

We have certifications such as:ATEX, IEC Ex, CE, CNEX, ISO14001, OHSAS18001,SIRA, DCI.

Application

Tubular heating elements are commonly used in industrial heating due to their versatility and affordability. They are used for heating liquids, solids and gases through conduction, convection, and radiation heating. Capable of reaching high temperatures, tubular heaters are an efficient choice for heavy duty industrial applications.

FAQ

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.What are the available product certifications?

We have certifications such as: ATEX, CE, CNEX. IS014001, OHSAS18001,SIRA, DCI. Etc

3.Which Items do you inspect in each processing stage?

External dimension; Insulation puncture test; Insulation resistance test; hydrotest…

4.What Type of package do you use?

Safe wooden case or as required.

5.How Do Tubular Heating Elements Work?

Tubular heating elements transfer heat through direct exposure to a liquid, solid, or gas. They are configured to a specific watt density, size, shapes, and sheath based on their specific application. They can reach temperatures of 750 degrees centigrade or higher when configured properly.

Production Process

Markets & Applications

Packing

QC & Aftersales Service

Certification

Contact information

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs of Manufacturing Companies for Explosion Proof Industrial Electric Heater - OEM industrial tubular heating elements – Weineng , The product will supply to all over the world, such as: Southampton, Hamburg, Palestine, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

We have been looking for a professional and responsible supplier, and now we find it.