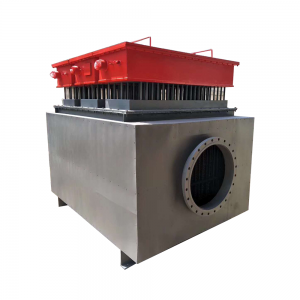

Electric air duct heater for industry

The electric heating tube adopts outer-wound corrugated stainless steel belt, which increases the heat dissipation area and greatly improves the heat exchange efficiency;

The heater design is reasonable, the wind resistance is small, the heating is uniform, and there is no high and low temperature dead angle;

Double protection, good safety performance. A thermostat and a fuse are installed on the heater, which can be used to control the air temperature of the air duct to work under the condition of over-temperature and seamless, ensuring foolproof.

The electric air heater has a wide range of use and can heat any gas. The hot air produced is dry and moisture-free, non-conductive, non-burning, non-explosive, non-chemically corrosive, non-polluting, safe and reliable, and the heated space heats up quickly ( Controllable).

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.What are the available product certifications?

We have certifications such as: ATEX, CE, CNEX. IS014001, OHSAS18001,SIRA, DCI. Etc

3.What is a duct heater for?

Duct heaters are commonly used to heat air and/or gas process streams in process heating or environmental room applications. Applications include: humidity control, machinery pre-heating, HVAC comfort heating.

4.How does an electric duct heater work?

Electric duct heater which makes use of electricity to warm the air that passes through a duct. It consists of a heating element which converts the electricity into heat through resistance. ... This results to efficient heat transfer without wasting energy as the room or space is only heated for the required times.

5.How is air heater capacity calculated?

When Calculating Heater Capacity, Use the Maximum Outlet Temperature and the Lowest Air Velocity. For Close Grouping of Heaters, Use 80% of the Calculated Value. 0 100 200 300 400 500 600 700 Outlet Air Temperature (°F) When Calculating Heater Capacity, Use the Maximum Outlet Temperature and the Lowest Air Velocity.