China Industrial Immersion Heater - Industrial Immersion Heater – Weineng

China Industrial Immersion Heater - Industrial Immersion Heater – Weineng Detail:

Feature

Use in tank heating, usually for stagnant liquid to heat up and maintain at certain desire temperature. Multiple immersion heaters are used for a bigger tank dimension where heat distribution can be spread more widely. Temperature control by means of ON/OFF thermostat or contactor is adequate where precise control is not required.

Typical Applications:

Closed Drain Drum

Open Drain Drum

Separators

Storage Tank

Lube Oil Reservoir

Application

Max power of single heater up to 2000KW-3000KW, maximum voltage 690VAC

ATEX and IECExapproved. Exd, Exe, IIC Gb, T1-T6

Zone 1 & 2 applications

Ingress Protection IP66

High quality anti-corrosion/high temperature heating element materials:

Inconel 600、625

Incoloy 800/825/840

Hastelloy, Titanium

Stainless steel: 304, 321, 310S, 316L

Design to ASME code and other International Standards.

Over-temperature protection on heating element/flange/terminal box by using PT100, Thermocouple and/or thermostat.

Flanged connection, ease of installation and maintenance.

Design for Life in cyclic or continuous operation.

FAQ

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.What are the available product certifications?

We have certifications such as: ATEX, CE, CNEX. IS014001, OHSAS18001,SIRA, DCI. Etc

3.What are the available heater fange type, sizes and materials?

WNH industrial electric heater, flange size between 6″(150mm)~50″(1400mm)

Flange standard: ANSI B16.5, ANSI B16.47, DIN, JIS (Also accept customer requirements)

Flange material: Carbon steel, Stainless steel, Nickel-chromium alloy, or other required material

4.What Type of package do you use?

Safe wooden case or as required.

5.How long is the warranty time for your product?

Our officially promised warranty time is 1 year after delivering at best.

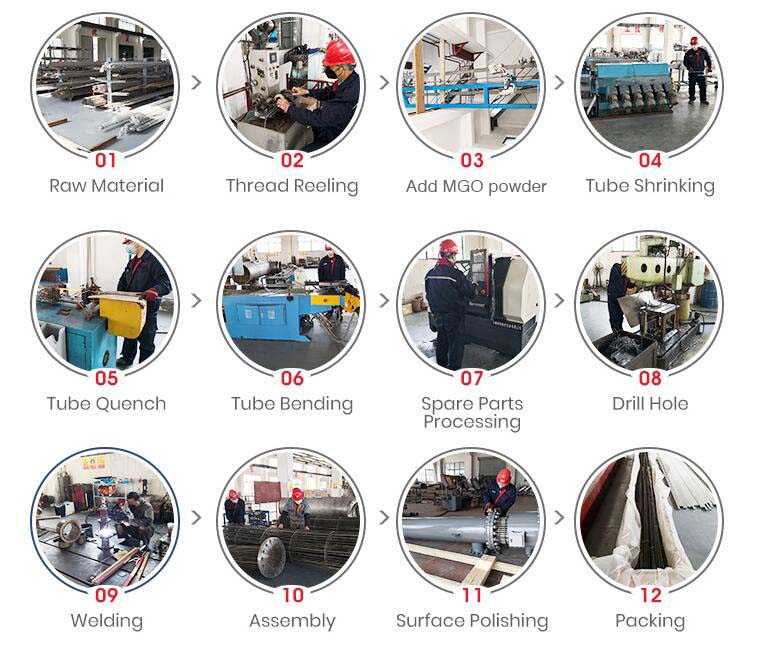

Production Process

Markets & Applications

Packing

QC & Aftersales Service

Certification

Contact information

Product detail pictures:

Related Product Guide:

To regularly increase the management program by virtue from the rule of "sincerely, good religion and high quality are the base of enterprise development", we greatly absorb the essence of linked products internationally, and constantly produce new goods to satisfy the calls for of shoppers for China Industrial Immersion Heater - Industrial Immersion Heater – Weineng , The product will supply to all over the world, such as: Pakistan, Sierra Leone, Philippines, The company attaches great importance to product quality and service quality, based on the business philosophy "good with people, genuine to whole world, your satisfaction is our pursuit". we design products, According to customer's sample and requirements, to meet the needs of the market and offer different customers with personalized service. Our company warmly welcomes friends at home and abroad to visit, to discuss cooperation and seek common development!

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.