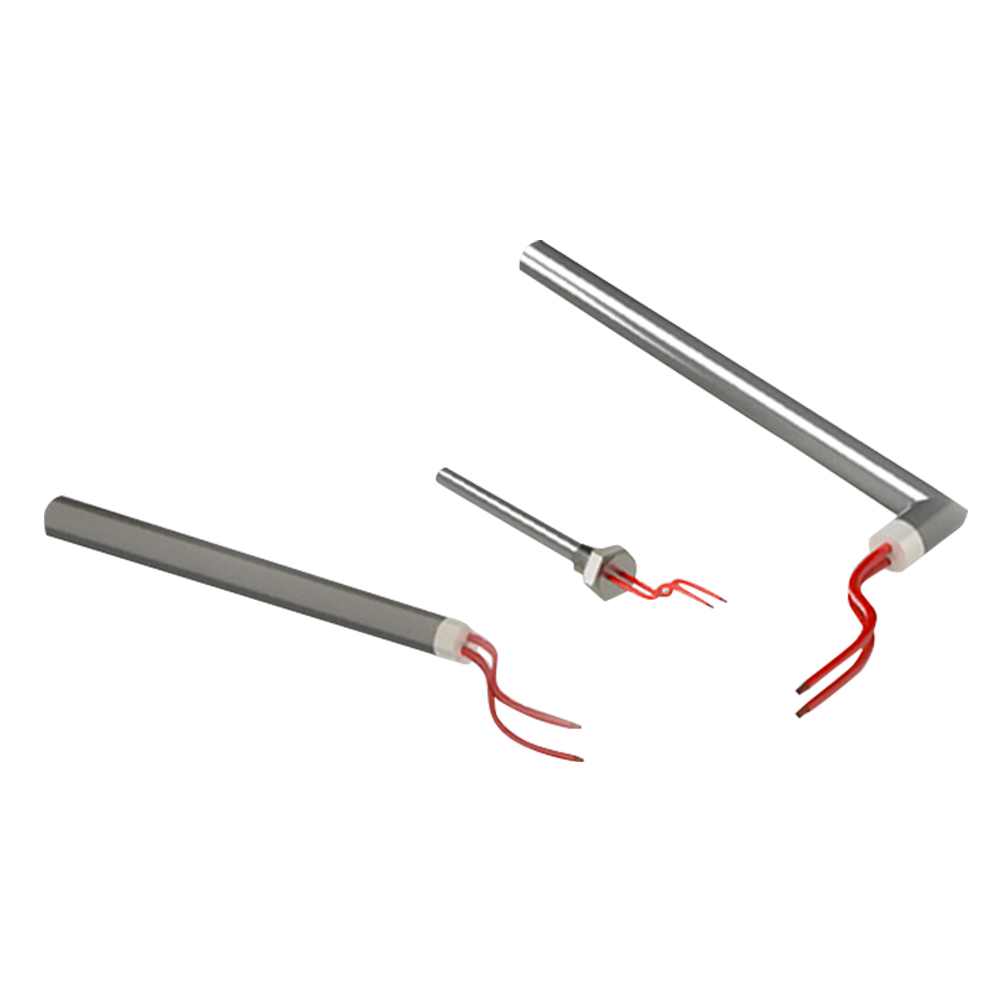

Cheapest Price Nitrogen Heater - OEM electric tubular heater – Weineng

Cheapest Price Nitrogen Heater - OEM electric tubular heater – Weineng Detail:

Feature

High quality raw materials:

Ni80Cr20 resistance wire

UCM high purity MgO powder for high temperature application

Tube materials available in: INCOLOY800/840, INCONEL600, Hastelloy, 304, 321, 310S, 316L and etc.

Key technical properties:

Leakage current : less than 0.5mA under operating temperature

Insulation resistance: cold state ≥500MΩ; hot state≥50MΩ

Dielectric strength: Hi-pot>AC 2000V/1min

Power Tolerance : +/-5%

Our products are UL and CE approved and meet the regulation requirements

Application

Tubular heating elements are commonly used in industrial heating due to their versatility and affordability. They are used for heating liquids, solids and gases through conduction, convection, and radiation heating. Capable of reaching high temperatures, tubular heaters are an efficient choice for heavy duty industrial applications.

FAQ

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.What are the available product certifications?

We have certifications such as: ATEX, CE, CNEX. IS014001, OHSAS18001,SIRA, DCI. Etc

3.What are available heater flange type, size and materials

WNH industrial electric heater, flange size between 6″(150mm)~50″(1400mm)

Flange standard: ANSI B16.5, ANSI B16.47, DIN, JIS (Also accept customer requirements)

Flange material: Carbon steel, Stainless steel, Nickel-chromium alloy, or other required material

4.What are the available element sheath materials

Available sheath materials include stainless steel, high nickel alloy and many others.

5.What are the ambient operating temperature limitations

WNH heaters are certifed for use in ambient temperature ranges from -60 °C to +80 °C.

Production Process

Markets & Applications

Packing

QC & Aftersales Service

Certification

Contact information

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to deliver you with great provider of processing for Cheapest Price Nitrogen Heater - OEM electric tubular heater – Weineng , The product will supply to all over the world, such as: Roman, Chile, United Kingdom, Be sure to feel cost-free to send us your specs and we are going to respond for you asap. We have got a experienced engineering team to serve for the every single comprehensive needs. Free samples may be sent for yourself personally to know far more facts. So that you can meet your desires, please actually feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!