Cheap price Tank Suction Electric Heater - Iron casted heaters – Weineng

Cheap price Tank Suction Electric Heater - Iron casted heaters – Weineng Detail:

Feature

Good heat transfer and high resistance to overheating.

Connection with IP55 protection box.

Portable for a quick placement on the top of the tank and an easy maintenance.

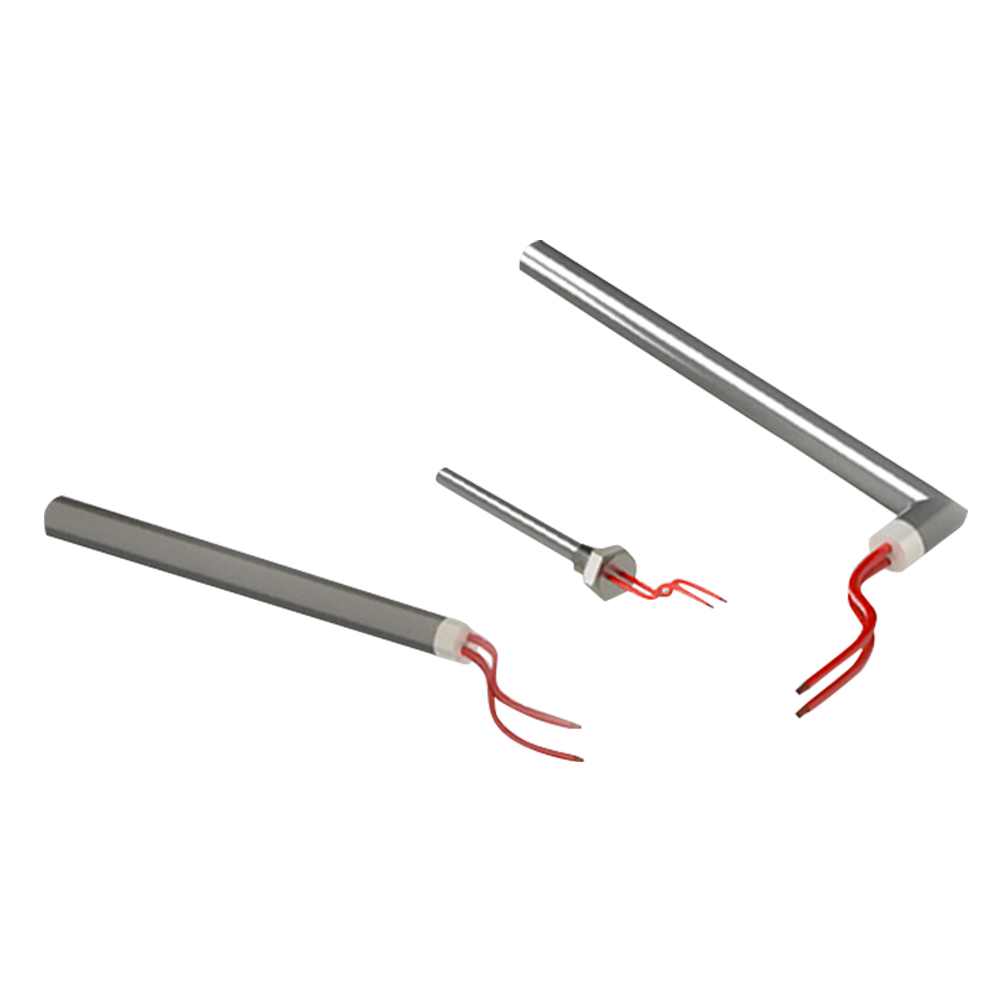

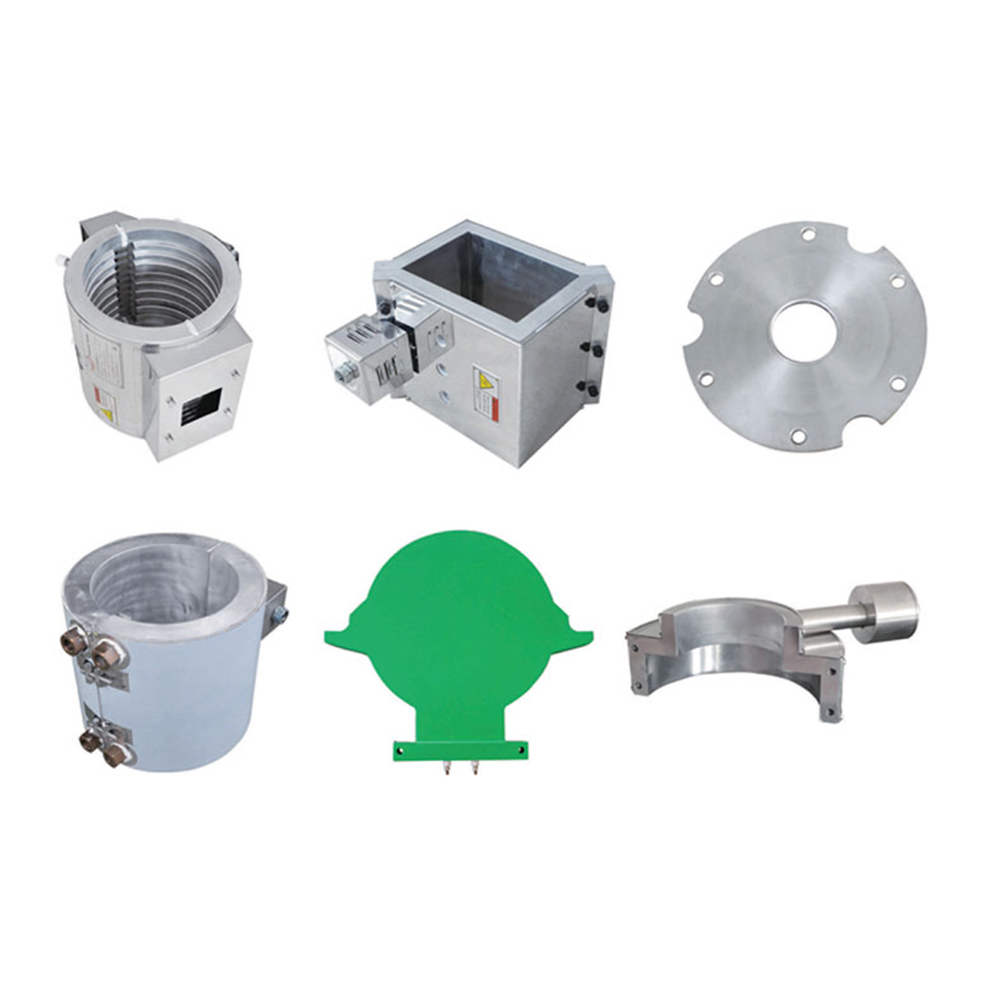

Cast in heaters can be manufactured with diffferent wattage, measures and shapes according to customer needs.

Flameproof IP66 rated terminal enclosure

Cellular Glass insulated with stainless steel cladding

Maximum design pressure and temperature of 660 barg at up to 400°C

Process control and over-temperature protection sensors: RTD Pt100, thermocouple type K or thermostats

Wall or floor, vertical or horizontal mounting

Multiple heating elements allow for step control; alternatively, solid state relay or thyristor control can be employed

Coil materials: stainless steel 316L, duplex S31803, super duplex S32760 (others, including nickel alloys available on request)

Process connections available using standard flanged or compression joints

Application

Seal gas

Air

Natural gas

Biogas

Paint heating

Nitrogen

CO2

Solvent

Instrument air

Pasteurisation

FAQ

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.What are the available product certifications?

We have certifications such as: ATEX, CE, CNEX. IS014001, OHSAS18001,SIRA, DCI. Etc

3.What type of temperature sensors are provided with the heater?

Each heater is provided with temperature sensors at the following locations:

1) on the heater element sheath to measure maximum sheath operating temperatures,

2) on the heater fange face to measure maximum exposed surface temperatures, and

3) An Exit temperature measurement is placed on the outlet pipe to measure the temperature of the medium at the outlet. The temperature sensor is a thermocouple or PT100 thermal resistance, according to customer requirements.

4.How to Choose an Industrial Heater?

It is important to consider the specifics of your application prior to selecting the heater to use. Of primary concern is the type of medium being heated and the amount of heating power required. Some industrial heaters have been specially designed to function in oils, viscous, or corrosive solutions.

However, not all heaters can be used with any material. It is important to confirm the desired heater will not be damaged by the process. In addition, it is necessary to select an electric heater that is appropriately sized. Be sure to determine and verify the voltage and wattage for the heater.

One important metric to consider is Watt Density. Watt density refers to the heat flow rate per square inch of surface heating. This metric shows how densely the heat is being transferred.

5.How long is the warranty time for your product?

Our officially promised warranty time is 1 year after delivering at best.

Production Process

Markets & Applications

Packing

QC & Aftersales Service

Certification

Contact information

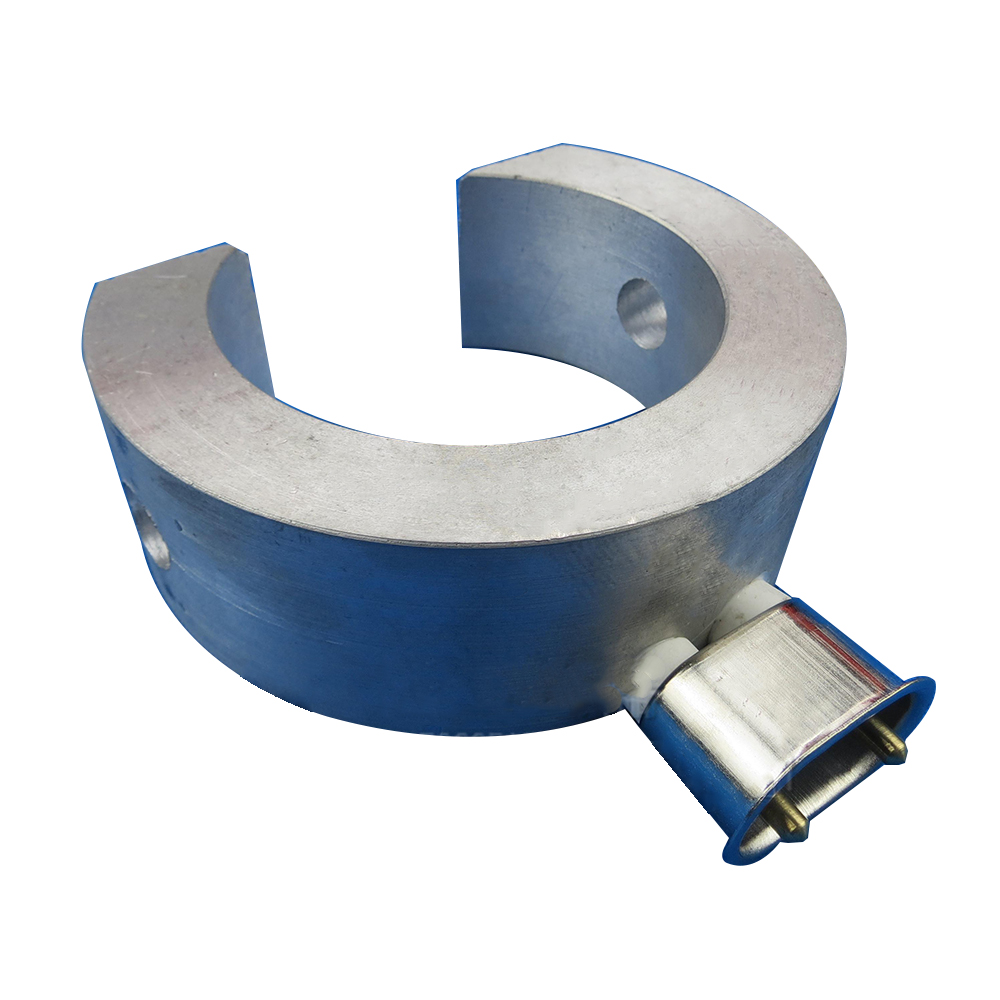

Product detail pictures:

Related Product Guide:

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for Cheap price Tank Suction Electric Heater - Iron casted heaters – Weineng , The product will supply to all over the world, such as: Bangladesh, Jordan, Malawi, We've got more than 10 years experience of production and export business. We always develop and design kinds of novel items to meet the market demand and help the guests continuously by updating our goods. We've been specialized manufacturer and exporter in China. Wherever you are, make sure you join us, and together we will shape a bright future in your business field!

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.