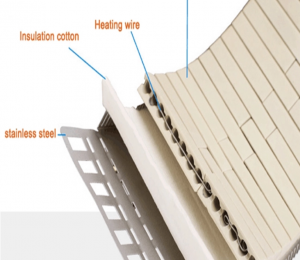

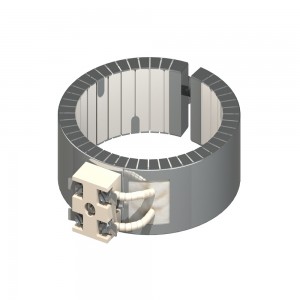

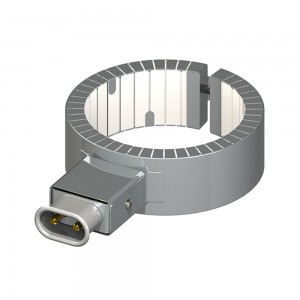

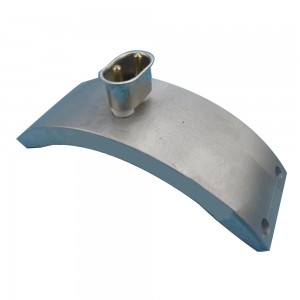

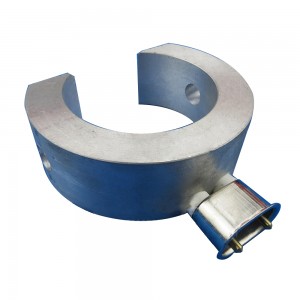

Ceramic band heater

The main advantage of ceramic heater units is that they can warm up instantly and it takes very little time for you to feel the heating effects of this type of heater. This design makes them some of the most efficient electric heaters available.

Typical applications are plastic molding, extrusion and molding presses. Ceramic band heaters are also used for pipe heating, heat treating and autoclaves or any application where there is a need to apply heat to a cylindrical surface.

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.What are the available product certifications?

We have certifications such as: ATEX, CE, CNEX. IS014001, OHSAS18001,SIRA, DCI. Etc

3.What is special about a ceramic heater?

Ceramic space heaters are electric, making them less complex than their oil counterparts. The ceramic heating element also heats up quickly, requiring less energy to get warmed up.

4.How hot do ceramic heaters get?

These qualities let ceramic heaters produce up to 1,000 W/in. 2 and operate at up to 600°C (1,112°F) depending on the heater design and process parameters. (Maximum and minimum power densities can vary with voltage, surface area, and application parameters.)

5.Do ceramic heaters use much electricity?

Ceramic heaters are highly efficient and operate on electricity. This means that there is no danger of toxic emissions such as carbon monoxide in the vicinity. When operated properly, ceramic heaters also consume lower amounts of electricity than other space heaters