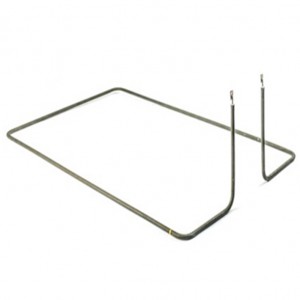

CE Certificated Single Ended Tubular Heaters

Single Ended Tubular Heating Elements are of similar construction as our standard tubular elements. They terminate at one end which can simplify wiring and installation. They are available in .315" and .475" diameters. These are most commonly used in molds and other heat transferring metal parts as well as open air applications and immersion applications. Tubular Heaters are available in a variety of sheath materials with temperature capabilities up to 1600°F (870°C).

Heating of Mould Tools, Tooling, Platens, Packaging Machinery, Heat Sealing Equipment, Plastic Process Machinery, Food Process Machinery, Catering, Printing, Hot Foil Printing, Shoe manufacturing Machinery, Laboratory / Test Equipment, Vacuum Pumps, and many more.

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.What are the available product certifications?

We have certifications such as: ATEX, CE, CNEX. IS014001, OHSAS18001,SIRA, DCI. Etc

3.How to choose an industrial heater?

It is important to consider the specifics of your application prior to selecting the heater to use. Of primary concern is the type of medium being heated and the amount of heating power required. Some industrial heaters have been specially designed to function in oils, viscous, or corrosive solutions.

However, not all heaters can be used with any material. It is important to confirm the desired heater will not be damaged by the process. In addition, it is necessary to select an electric heater that is appropriately sized. Be sure to determine and verify the voltage and wattage for the heater.

One important metric to consider is Watt Density. Watt density refers to the heat flow rate per square inch of surface heating. This metric shows how densely the heat is being transferred.

4.What type of package do you use?

Sofe wooden case or as required.

5.How long is the warranty time for your product?

Our officially promised warranty time is 1 year after delivering at best.