Best Price for Anti-Explosion Circulation Heater - CE certificated electric tubular heater – Weineng

Best Price for Anti-Explosion Circulation Heater - CE certificated electric tubular heater – Weineng Detail:

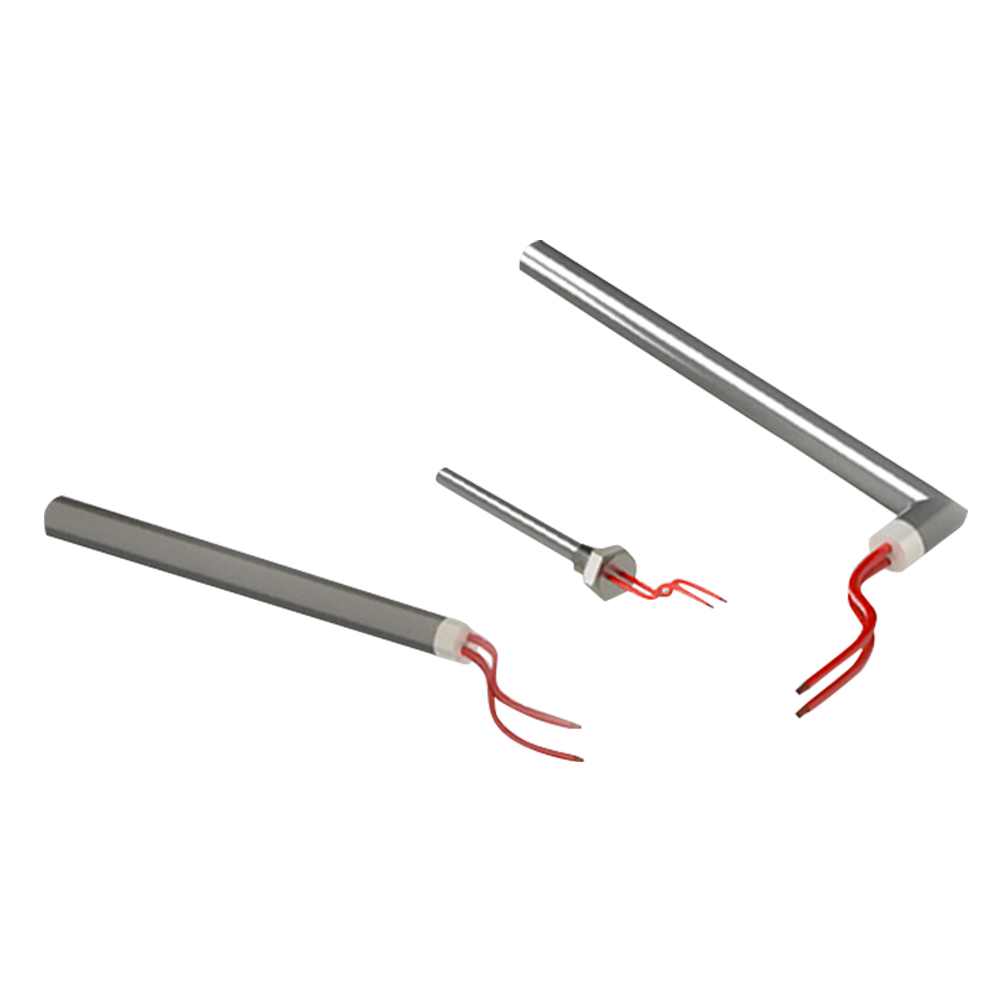

Feature

High quality raw materials:

Ni80Cr20 resistance wire.

UCM high purity MgO powder for high temperature application.

Tube materials available in: INCOLOY800/840, INCONEL600, Hastelloy, 304, 321, 310S, 316L and etc.

Key technical properties:

Leakage current : less than 0.5mA under operating temperature.

Insulation resistance: cold state ≥500MΩ; hot state≥50MΩ.

Dielectric strength: Hi-pot>AC 2000V/1min.

Power Tolerance : +/-5%.

We have certifications such as:ATEX, IEC Ex, CE, CNEX, ISO14001, OHSAS18001,SIRA, DCI.

Application

Tubular heating elements are commonly used in industrial heating due to their versatility and affordability. They are used for heating liquids, solids and gases through conduction, convection, and radiation heating. Capable of reaching high temperatures, tubular heaters are an efficient choice for heavy duty industrial applications.

FAQ

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.What are the available product certifications?

We have certifications such as: ATEX, CE, CNEX. IS014001, OHSAS18001,SIRA, DCI. Etc

3.What us the maximum power density of the heater?

The power desity of the heater must be based on the fluid or gas being heated. Depending on the specific medium, the maximum usable value can reach 18.6 W/cm2 (120 W/in2).

4.Can I order one for each for sample?

Yes , of course.

5.What type of package do you use?

Normally wooden case, or as required.

Production Process

Markets & Applications

Packing

QC & Aftersales Service

Certification

Contact information

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for Best Price for Anti-Explosion Circulation Heater - CE certificated electric tubular heater – Weineng , The product will supply to all over the world, such as: Cancun, Porto, Cape Town, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you personally.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!