2021 Latest Design Sulfur Recovery Explosion-Proof Electric Heater - Finned tubular for air duct heater – Weineng

2021 Latest Design Sulfur Recovery Explosion-Proof Electric Heater - Finned tubular for air duct heater – Weineng Detail:

Feature

Shielded heating elements in AISI 304 of φ10mm;

Stainless steel AISI 430 fin of φ26mm outer diameter.

Ni-Cr alloy resistive wire.

Zinc steel M14 crimped connectors

Sealed with silicone (up to 200C on continous)

Threaded connection of M4 or M6 depending on models.

Standard voltage ~230V

All stainless steel;

Spiral fin:

for φ8mm pipe: stainless steel finning – >φ18,φ24 iron fining – φ23

for φ10mm pipe: stainless steel finning – >φ20,φ26, φ30 iron fining – φ25, φ 30

Other dimensions, wattages and voltages available on request

Finned tubular air heating elements are constructed like basic tubular elements with the addition of continuous spiral fins, 4-5 per inch permanently furnace brazed to the sheath. Fins greatly increase surface area and permit faster heat transfer to air, resulting in lower surface element temperatures.

Application

To heat forced circulation air for heating premises, closed drying circuits in heaters, charge benches, etc.

In general, for any application of forced air heating up to 200C (Maximum temperature with vair = 4m/sec ->200C)

FAQ

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.What are the available product certifications?

We have certifications such as: ATEX, CE, CNEX. IS014001, OHSAS18001,SIRA, DCI. Etc

3.What are the available element sheath materials

Available sheath materials include stainless steel, high nickel alloy and many others.

4.Can WNH provide anti-condensation heaters to prevent damage from moisture?

Yes, an anti-condensation heater can be provided within the heater terminal enclosure, based on customer specifcations.

5.How long is the warranty time for your product?

Our officially promised warranty time is 1 year after delivering at best.

Production Process

Markets & Applications

Packing

QC & Aftersales Service

Certification

Contact information

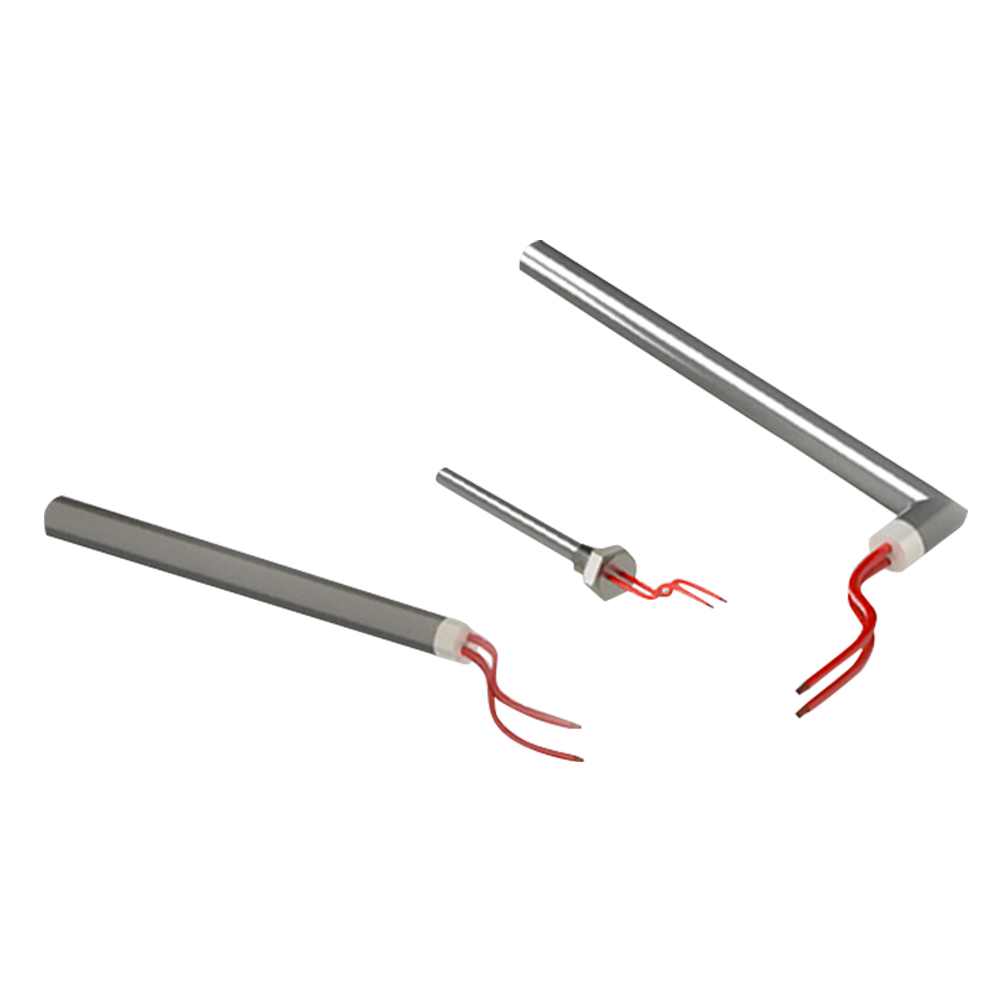

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of 2021 Latest Design Sulfur Recovery Explosion-Proof Electric Heater - Finned tubular for air duct heater – Weineng , The product will supply to all over the world, such as: Russia, Monaco, azerbaijan, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products we offer, effective and satisfying consultation service is supplied by our specialist after-sale service group. Solution lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we are going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!