2021 China New Design Atex Certificated Flow Heater - Industrial electric heater for harzardous area – Weineng

2021 China New Design Atex Certificated Flow Heater - Industrial electric heater for harzardous area – Weineng Detail:

Feature

Max power of single heater up to 2000KW-3000KW, maximum voltage 690VAC

ATEX and IECExapproved. Exd, Exe, IIC Gb, T1-T6

Zone 1 & 2 applications

Ingress Protection IP66

High quality anti-corrosion/high temperature heating element materials:

Inconel 600

Incoloy 800/825/840

Hastelloy, Titanium

Stainless steel: 304, 321, 310S, 316L

NiCr 80/20 heating wires, single or double coils.

Design to ASME code and other International Standards.

Hair-pin element and sealing to tubesheet by means of Bite-Coupling or Direct Welding. When use with Bite-coupling, individual element can be replaced (offline).

Over-temperature protection on heating element/flange/terminal box by using PT100, Thermocouple and/or thermostat.

Flanged connection, ease of installation and maintenance.

Design for Life in cyclic or continuous operation.

Explosion Proof

Application

Immersion heaters from WNH are used for applications such as the following:

lubricating oil heaters for turbines, compressors, pumps, refrigeration machines

heaters for heat transfer oil, heavy oil, fuels

container heaters for process water and emergency showers

heating of process gases

motor anticondesnation heaters

container and heating chamber heating

Area

Process heaters

Tank or lube oil heaters for large machines

FAQ

1.Are you factory?

Yes, we are factory, all customers are more than welcome to visit our factory .

2.What are the available product certifications?

We have certifications such as: ATEX, CE, CNEX. IS014001, OHSAS18001,SIRA, DCI. Etc

3.What are the available heater fange type, sizes and materials?

WNH industrial electric heater, flange size between 6″(150mm)~50″(1400mm)

Flange standard: ANSI B16.5, ANSI B16.47, DIN, JIS (Also accept customer requirements)

Flange material: Carbon steel, Stainless steel, Nickel-chromium alloy, or other required material

4.Can WNH provide pressure vessels suitable for use with the process heaters?

Yes,WNH can provide pressure vessels suitable for use with the electric heaters according to customer requirements.

5.Which Items do you inspect in each processing stage?

External dimension; Insulation puncture test; Insulation resistance test; hydrotest…

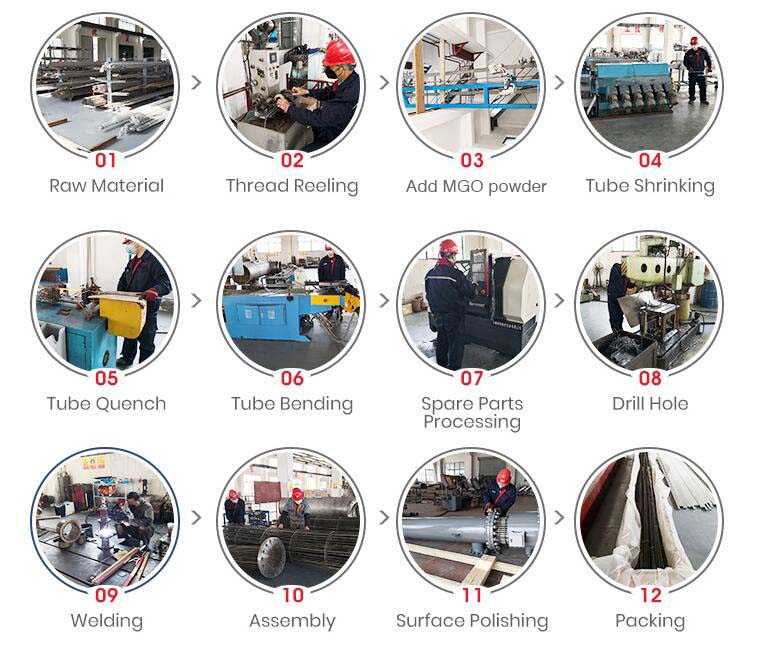

Production Process

Markets & Applications

Packing

QC & Aftersales Service

Certification

Contact information

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, have confidence in the very first and management the advanced" for 2021 China New Design Atex Certificated Flow Heater - Industrial electric heater for harzardous area – Weineng , The product will supply to all over the world, such as: Germany, Yemen, Germany, Our advantages are our innovation, flexibility and reliability which have been built during last 20 years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.